ZF’s Commercial Vehicle Solutions (CVS) division and Volta Trucks, a leading and disruptive all-electric commercial vehicle manufacturer and services provider, have announced a long-term agreement, for some of the core systems and components in the all-electric Volta Zero.

“Especially agile, new truck manufacturers like Volta Trucks need strong partners in their supplier base helping them to reduce R&D costs and shorten the time-to-market, by offering turn-key solutions, as well as related application engineering and testing support. With the commercial vehicle industry’s broadest product portfolio providing a favorable mix of established and innovative solutions, ZF is well-positioned to accompany commercial vehicle manufacturers on their way towards increasing levels of electrification, automation, and digitalization. We are proud to partner with such an innovative brand like Volta Trucks to support the industry’s transformation towards zero emissions and zero accidents”, said Dr. Peter Laier, Member of the Board of Management with responsibility for ZF’s Commercial Vehicle Solutions division.

Ellie Pittson, Purchasing Director at Volta Trucks said; “As a disruptive all-electric manufacturer that is bringing a vehicle to market at an industry-setting pace, partnering with trusted automotive suppliers such as ZF will be a vital part of our success. Volta Trucks and ZF have a shared commitment towards climate protection and sustainability, and lead the field for next-generation mobility, which makes this relationship a very important one for Volta Trucks.”

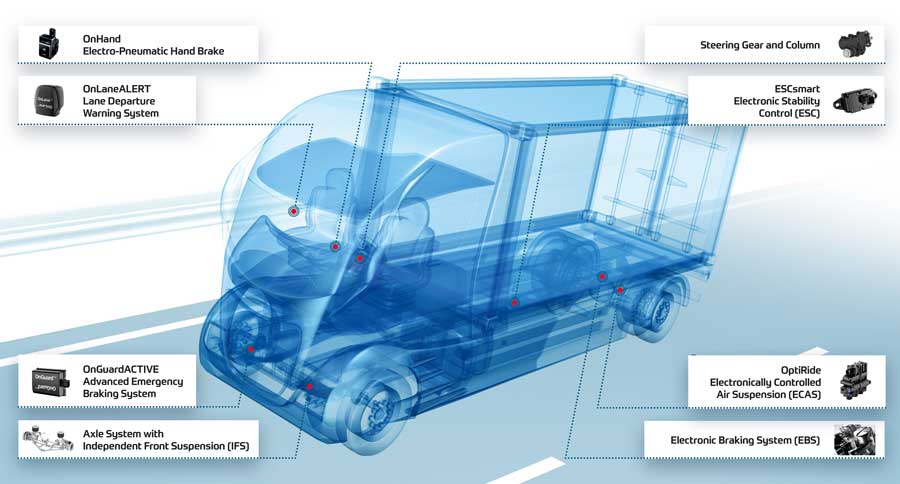

Chassis and Safety Technologies at the heart of Volta

ZF technologies fitted to the Volta Zero have been designed and configured specifically for commercial vehicle use and form part of the key systems. These systems include the OnGuardACTIVE Advanced Emergency Braking System (AEBS), Electronic Braking System (EBS) including the brake pedal box, ESCsmart Electronic Stability Control (ESC), and OnHand Electro-Pneumatic Handbrake (EPH). The OnLaneALERT Lane Departure Warning System (LDWS), which enhances safety and helps to prevent unintended lane drifts, is also sourced from ZF as well as components in the steering system including the steering column and the steering gear. In addition, ZF’s OptiRide Electronically Controlled Air Suspension (ECAS) system fitted to the Volta Zero supports daily vehicle operations including docking and loading procedures through automatic and manual chassis height adjustments for improved driver safety, efficiency, and comfort.

Front Axle System with Independent Suspension for Trucks

Furthermore, Volta equips its all-electric truck with ZF’s innovative axle system with independent front suspension (IFS). Having been proven in thousands of bus applications, recently ZF made this axle technology also available for truck applications. ZF’s IFS axle system provides a smart ‘turnkey’ solution for new automotive customers that outsource their vehicle axles. In support of the architectures of manufacturers’ electrification strategies, IFS maximizes space for electric components and batteries.

With its compact and optimized design, it supports the low cabin for ease of ingress and improved driver vision. A wide range of RL 82 ET IFS with varied control arms, enables vehicles with a width of 2,300 mm to 2,600 mm and up to 8,200 kg axle load to be supported. ZF’s RL 80 ET IFS is also available to meet the specific vehicle width and wheel sizes of the North America market.

ZF’s IFS solution powerfully combines optimum steering behavior with advanced ride comfort. With optimized unsprung mass, air spring suspension and ZF PCV shock absorber technology, the IFS axle technology helps protect the truck’s battery and electrical components. It also enables a high level of maneuverability and, depending on the tires fitted, a steering angle of up to 56° is possible, which significantly reduces the truck’s turning radius. Supporting driving safety, the IFS axle system provides optimal lane keeping and cornering stability while eliminating undesired bump and brake steering influences. Offering superior roll stiffness, anti-roll bars are no longer necessary in most applications.

Building on over three decades of experience in the development and manufacturing of front axles worldwide, ZF has more than 3,800 axle-experienced service stations globally.