Fewer accidents and lower fuel consumption as well as more safety and climate protection: The EU Commission and the United Nations Economic Commission for Europe have made tire monitoring systems mandatory. The directive came into force for new vehicle type approvals from July 2022 and for new registrations from 2024. Low tire pressure is the cause of 85 percent of total tire failures. Constantly correct tire pressure, on the other hand, improves road safety, extends the service life of the tires, and effectively reduces fuel consumption. To meet the new requirements and to prepare trucks and trailers for the future, SAF-HOLLAND has made the SAF TIRE PILOT – a product that has been successful for more than ten years – digital.

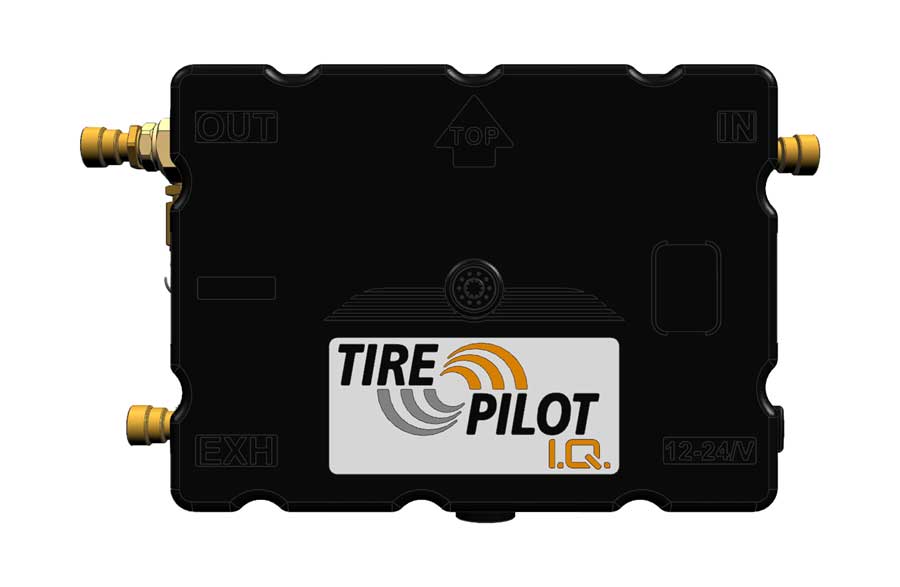

Smart, digital, connected: SAF TIRE PILOT I.Q.

Just as the previous model, the digital SAF TIRE PILOT I.Q. helps drivers and fleet managers to continuously monitor and consistently maintain tire pressure. “The display in the driver’s cab warns the driver when the pressure falls 0.5 bar below the set value in the system. If the pressure drops below this value, the system tops up the air automatically, without any interaction from the driver,” says Benjamin Irmscher, Product Line Manager Axles & Suspensions at SAF-HOLLAND. The system is available for all trailers with rigid and steering axles.

In addition to the warning message on the dashboard in the cab, SAF TIRE PILOT I.Q. offers detailed evaluations via an app and WiFi. The free app supplies detailed real-time data about the system status.

Trailer manufacturers benefit from the easy installation of the smart system: The control module is compatible with all types of trailers with single and dual tires and with up to five axles. As the EBS system supplies the SAF TIRE PILOT I.Q. with power and also delivers the system messages to the dashboard, the control box is installed close to it on the chassis. An EoL test is easily possible with the digital assistant. Another bonus: No allocation of wheel and sensor is required.

More safety due to fewer tire failures

With the SAF TIRE PILOT I.Q. tire-inflating system, tire failures due to gradual loss of air are a thing of the past. Trailers, for example, do not break down even in the event of a puncture, but can safely reach their destination or the closest repair workshop. The early warning from the system prevents numerous accidents caused by tire debris on the road.

SAF-HOLLAND supports environmental protection

“Monitoring tire pressure is not only mandatory, but also a question of costs and climate protection. Our monitoring and top-up system has a positive impact on fuel consumption and tire wear,” says Benjamin Irmscher, Product Line Manager Axles & Suspensions at SAF-HOLLAND. As the Fraunhofer Institute for Environmental, Safety and Energy Technology discovered in 2018, tire wear is by far the most prolific source of microplastics. In addition to this, tire manufacturing requires large amounts of energy – around 60 per cent of a tire is made from mineral oil.

As the associated amortisation calculator at http://tirepilot.safholland.com shows, the SAF TIRE PILOT I.Q. from SAF-HOLLAND can save up to 1,100 euros over 100,000 kilometres. Only a few details about the characteristics of the semi-trailers and the annual tire expenses are required for the calculation.