Interview by Gianenrico Griffini

I really feel honored to be here today in a very historical moment for MAN the, let me say, official opening of the assembly line for the electric trucks. Can you explain the main technical characteristics of this assembly line?

To be honest, if we talk about the electric trucks, the main characteristic of this assembly line is that it is not a different assembly line from our diesel assembly line, because right from the beginning, we had the idea and the vision in place that we said, okay, we should create an integrated system. We were clear that it is maybe not so easy to predict also how volumes will ramp up and for how the speed is.

So we thought that okay, to be fully flexible for the needs of our customers, the best thing is to integrate all in one and to run a system that we can scale easily because it’s not dependent on a good forecast.

What are the main differences between, a diesel truck assembly line and this assembly line? You already said to me that you can switch from one type of truck to the other, but what are the main, differences.

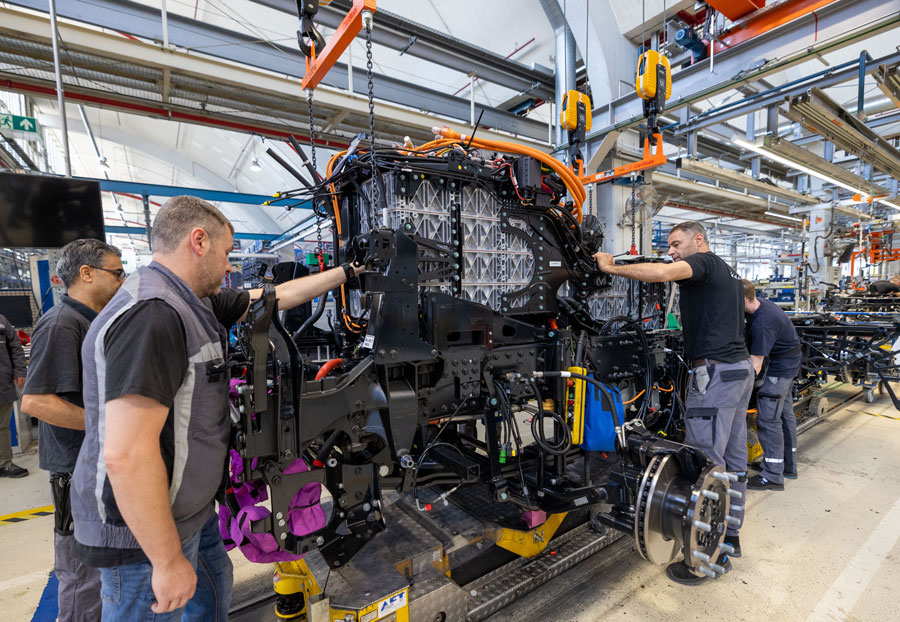

Yes, of course there’s differences now because the products are different and the driveline is different. And of course, that makes also some challenges in order to come to a system that is, at the end, fully integrated. One of these differences, for example, is purely the number of parts we assemble. So it’s 30% more parts that would go into an electric truck assembly than in a diesel truck assembly.

And of course, we needed to find a way how to master that challenge. And we thought a long time with engineering also how we could do and then came up with the modularity especially that is super important here, that we could do certain things in pre assembly steps independent from our line speed, mastering the different complexity of a diesel and an electric truck, and then combining it to the assembly line again with processes that are many times the same, or even if they are different, they can be mastered by our teams in the same time.

And that is why the cooperation also with engineering was super important to design the product in a clever way, always with the target, not only to make the best possible e truck, which is of course first always the target to make the product in itself perfect, but also to find a way how to cleverly industrialize the product and to make it fit into a combined system.

And how do you manage to have a mixed production to you? Just explained me something, but I think it’s not easy to since you don’t know the volumes, but you have to mix this product.

Yeah. First of all, how we set up all processes and how we designed at the end, also the assembly system, but also the logistics system behind. It was always looking also at the sage of a pure electric production. So we always had in mind also the shortest possible, times the biggest possible volume in order to see, okay, how do we have to design the system so that it can scale from 0 to 100 one a day?

And, that was of course, important to not just get surprised. Today of course, we need some kind of planning, advancement also. I mean, our supply base, they will not be ready from today to tomorrow to triple the volume, of course, that need some forecasting and, but that is not much different to what the normal production would also be just demanding.

There also is also a supply chain to follow. And in other ways, of course, it’s a question of qualification. So we needed of course also to train our team. We have trained more than 5000 people here in Munich, not only production but also all service departments dealing with production together in order to know what they have to maybe behave differently also with electric trucks, to make them sensitized, at least, or even having really high level of high voltage knowhow in itself. So also the team, of course, is a part of it. And we started with a smaller part of the team in our e-mobility center, where we developed the pre serial vehicles, where we developed the production process, where we trained people to be later train the trainer. And that is now what we are profiting on in scaling up, also the competence level of the full team.

How do you manage to, integrate the supply line? because you already explained me that there are more components for, for an electric truck. How do you manage to organize the supply line, the supply chain? Compared to a standard diesel truck?

I mean, first of all, we need to say that the electric part truck is part of a same modular system. So it’s not a completely different truck. And we also share quite many components and suppliers for components with a diesel truck. But of course, there is also specific parts and specific components that are only needed for battery electric.

And we have also some suppliers which are exclusive in the production of parts for battery electric. But they are integrated in a logistics manner in the same way as all the other ones. The complexity, of course, is rising at our plant because we get now more components than what we ever had, producing more or less the same number of vehicles, but with many more different parts.

So the logistics system needed to be upgraded. But we already were quite, let’s say, in a pool system even before where many of the parts were pre commissioned in logistics steps, either in our plant or even at a supply base, then coming just in time, just in sequence to the assembly line, especially to only fit the next couple of trucks so that we will not have super many containers and not we have to increase the number of containers at the assembly line, but can keep the space for the processes now.

So we even increased, I would say, the pull principle in our assembly, to get just that material to the line that is needed for the next couple of trucks. And that helps us, of course, to master also a bigger complexity. But of course, this complexity still exists. It is now just offloaded to the logistics processes, either in the plant or at the suppliers.

How did you organize the quality control? Do you have the same quality gate of the diesel truck, or do you have a special quality gate for electric trucks?

I mean, we know and understand, of course, first of all, that the quality level we need to achieve, our customers would expect for us does not differ any between the diesel and electric truck. So the target is at the end to reach at least the same quality, of course, and that high quality level, our customers are normally used from an MAN vehicle.

And we ensure that first of all, with the same quality assurance system. Also, we had in the past only for diesel trucks and of course in some of our quality gates, there is specific quality criteria which we defined to check the specific characteristics of an electric truck, but it is also here integrated into the same system.

And of course, we work quite a lot on the competence level of our employees. And in some areas also we do, let’s say a little bit automatic testing, that is then specific for the electric trucks and for the diesel trucks, somewhat different, in order to support that zero defect policy, which we would have anyway. So at the end, it is, I would say, an extension of the existing system with the same main principles in order to really ensure zero defect production or if something happens, we are able to detect it in the plant.

But competence for our people, that is the key in it.

And one last question. What about, let me say the maximum installed capacity. You have just started now, and so it’s a difficult question and you don’t know, let me say, the evolution of the demand for electric truck, but the maximum installed capacity so far. Yeah.

I mean here in the system, we are currently producing 50 trucks in a shift, two shift operation so we can produce 100 trucks per day. That system could further scale without any further investments also to 65 and a shift to 130 in a day. And we can produce as many electric as we can produce at all. So the system here can scale, let’s say, from zero up to maximum 130 trucks a day.

And some day we will also exceed that capacity most likely. That’s why everything that we did today, from a planning perspective, is also suited to go into our sister plant in Niepołomice in Krakow in Poland, where the cycle time would be even faster, slightly. So we are operating here at the cycle time of eight minutes, 8.5 minutes.

But the process we can also implement in a system that runs 4.5 minutes. So that means we can scale of course, also further up, even if the Munich capacity is expired. But for the next couple of years, we believe that the Munich capacity will first of all be sufficient for the heavy duty trucks. Light duty trucks, medium duty trucks they will be exclusive in the Polish system as they are today.

And also here, of course, we will start next year with serial production of the electric vehicles.

Thank you very much for your answer and for the interview.

Thank you very much for coming and was a pleasure to have you here. Thank you.