MAN Truck & Bus is participating in the “Mobility Study on Low-Noise Logistics” conducted by the Fraunhofer Institute for Material Flow and Logistics IML and sponsored by the Ministry for the Environment, Nature Conservation and Transport of the State of North Rhine-Westphalia. Its aim is to develop standards for measuring noise emissions during delivery operations. MAN was part of the real-world measurements with selected vehicles using a pre-production vehicle of the new MAN eTruck, which will be delivered to customers for the first time in 2024. The result: electric trucks are perceived – especially at low speeds – as only about half as loud as comparable diesel trucks.

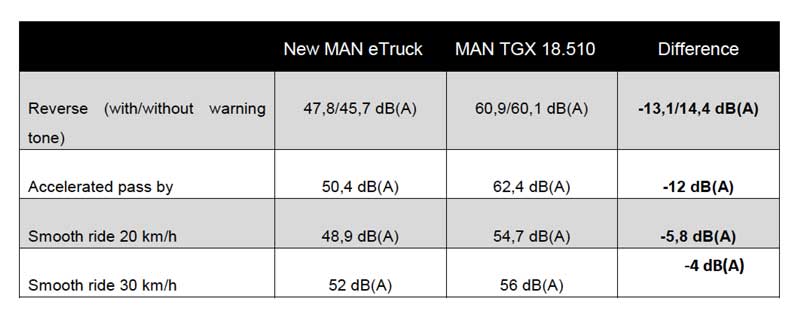

“Based on the measurements, the level for the eTruck is about 6 dB lower for steady passing at 20 km/h. If one takes into account here that the diesel truck measured here is about 5 dB quieter at 20 km/h than the typical approach from the literature, the difference between the eTruck and the literature approach increases to 11 dB. The eTruck is thus about half as loud as a classic diesel truck in terms of auditory impression. For the accelerated approach, there was an even more significant level difference between the two trucks of 12 dB,” explains Michael Wirtz, project manager of the measurements at Peutz Consult GmbH. In order to be able to classify the noise development of the MAN eTruck even better, Wirtz draws a comparison with conventionally driven passenger cars: “With a sound power level of approx. 49 dB(A)/m at 20 km/h, the eTruck is only 1dB ‘louder’ than the passenger car with 48 dB(A)/m.”

Dr. Christoph Jeßberger, Product Strategy Manager at MAN, also draws a positive balance: “With the MAN eTruck, we want to make a positive contribution to people and nature. We do this primarily with the local freedom from emissions, but also with the clearly perceptible noise reduction. The measurements show: Our new MAN eTrucks could also be used during off-peak hours, i.e., late in the evening or early in the morning. This means they open up a very wide range of uses and a high degree of flexibility for our customers. This means use up to 24 hours a day, 7 days a week – provided the legal framework is in place.”

The importance of these efforts is demonstrated by the noise and sound insulation requirements in many approval procedures. The Netherlands, for example, has developed the PIEK noise protection standard. In order to obtain certification – for night deliveries, for example – trucks and the transport equipment are acoustically tested. They must not exceed the prescribed decibel limits at a distance of 7.5 meters. In Germany, noise immissions are assessed according to the TA Lärm (Technical Instructions on Noise Protection).

“There is currently no market overview or standardized information on noise emissions from alternatively powered commercial vehicles used in logistics in Germany,” says Daniela Kirsch, project manager at Fraunhofer IML, explaining the problem in Germany. “That’s why we need a solution like the PIEK certificate that companies can use for orientation.”

No orientation values for permits Getting new permits for deliveries at night or during off-peak hours is still often difficult today because there is a lack of values that administrations can use for orientation. “By producing a manual on noise emissions from trucks with alternative drive systems during deliveries in urban areas, we want to make the work of municipalities and permitting authorities easier. We have found that they lack data and measured values if they are to decide, for example, on nighttime delivery in urban areas,” says Kirsch. The Fraunhofer study on low-noise logistics aims to change that.

Study setup and measurement methods

The study is expected to be published in early 2024. The data for it was collected, among other things, during a series of measurements on the MAN test track in Munich. Experts sent the MAN eTruck and a conventional diesel-powered MAN TGX 18.510 of the same weight class onto the track and measured their noise levels. The trucks in question were semitrailer trucks with a total weight of 40 tons. Employees of the accredited measurement center Peutz Consult GmbH carried out the measurements on behalf of Fraunhofer IML. They set up calibrated hand-held sound level meters on the right and left of the carriageway, each at a distance of 7.5 m.

Various scenarios were simulated on the MAN test track and their noise immissions measured: Firstly, driving at 20 km/h with the AVAS acoustic warning system switched on – this involves artificial driving noises because the rolling noise of the tires can only be clearly heard above a speed of approx. 20 km/h. Further measurements were taken at 30 km/h and when reversing with the reversing warning system switched on and off. In addition, data was collected on the accelerated approach. Each measurement was performed at least ten times.

Result of the measurements in Munich