Technological diversity is key to fast decarbonization of the global transportation and commercial vehicle sector. “The wide variety of applications and requirements for today’s commercial vehicles will require an array of technical solutions for sustainable drive systems which are just as multifaceted”, said Arnd Franz, Chairman of the MAHLE Management Board and CEO, at a technology event in Stuttgart. MAHLE is therefore broadly positioned with components and high systems expertise for battery electric drives, hydrogen engines, fuel cells and the use of renewable fuels in order to actively shape tomorrow’s climate-friendly transportation sector. The automotive supplier is extensively represented with components in all electrified trucks that are currently being launched. In addition, the group is involved in all current major hydrogen engine projects and development projects for fuel cell vehicles. MAHLE supplies over 120 international commercial vehicle brands in the on- and off-highway sector. The commercial vehicle segment accounts for about one-fifth of the company’s original equipment business, and the trend points up. MAHLE expects particularly strong growth in China. At the international commercial vehicle trade fair “IAA Transportation” in September, the automotive supplier will present its systemic approach to a fuel cell truck: with fuel cell peripherals, thermal management, and a fully functional electric axle with two integrated SCT electric motors. Other world premieres include a new evaporative cooling system and a bionic fan for demanding fuel cell and electric vehicles. “Our products are developed, tested and ready for volume production,” Franz said. The IAA Transportation takes place from 17 to 22 September in Hanover, Germany. The MAHLE stand is located in Hall 12.

Commercial vehicles are the backbone of the global economy. 80% of overland transport is carried out by commercial vehicles. Each individual truck has an average annual mileage of 150,000 km to keep the flow of goods in the economy flowing. The need for transport will continue to grow. “Without the contribution of the transportation sector, there will be no rapid decarbonization in transport,” emphasized Arnd Franz. The industry must strike a balance between necessary climate protection, global market developments and customer requirements for reliable and affordable transport.

According to forecasts, purely electric trucks with batteries and fuel cell trucks will account for around 30 percent of global production by 2035. This means that the internal combustion engine will remain an essential drive system around the world for the foreseeable future. Battery-electric drive systems will mainly be used in the medium-duty truck segment and in the heavy-duty truck segment on short-haul routes. Fuel cells and combustion engines, powered by either hydrogen or other renewable fuels, capitalize on their advantages on the long haul. MAHLE therefore stands for technological diversity and, with its three strategic fields of electrification, thermal management, and highly efficient sustainable combustion engines, develops the best solutions for every use case worldwide. In this way, the company enables the reduction of the carbon footprint of road freight transport.

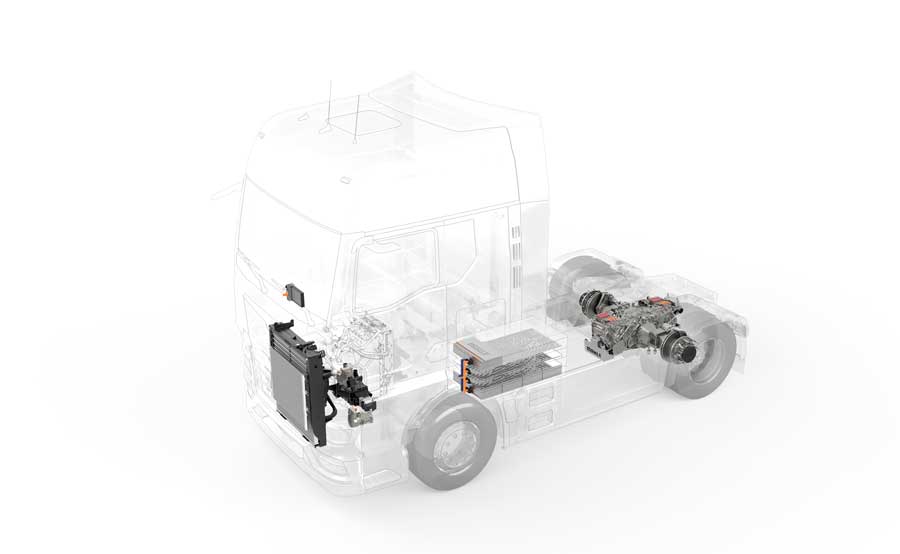

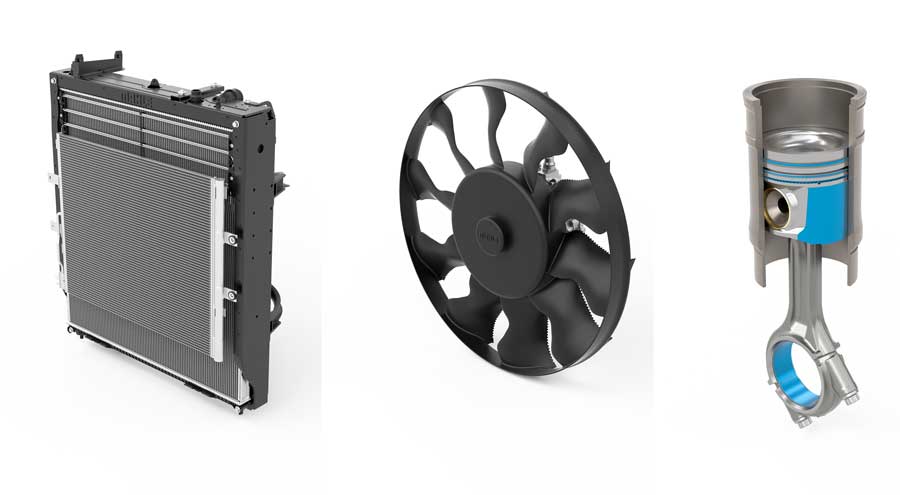

The MAHLE SCT electric motor (Superior Continuous Torque) is the endurance champion among electric motors. Its high continuous power and efficiency make it the ideal electric drive for heavy-duty traffic in all-electric trucks and in fuel cell applications. At the IAA Transportation, MAHLE will show a heavy-duty e-axle for the first time, in which two SCT electric motors with a total output of 520 kW as well as the complete liquid management are compactly integrated, demonstrating its systems expertise and the suitability for series production of its innovations.

Together with a fully functional fuel cell, the e-axle, battery cooling and fuel cell peripherals from MAHLE form a technology exhibit. “This demonstrates how we can integrate our technologies, including thermal management, into electric vehicles and thus develop and optimize a wide range of options for different customer applications,” said Dr. Marco Warth, Vice President Corporate Research and Advanced Engineering at MAHLE.

The conversion of hydrogen into electricity in the fuel cell places high technical demands on the vehicle—particularly with regards to thermal management. MAHLE plays a leading role in this field of technology. Also part of the technological exhibit is the evaporative cooling device, presented as a world first at the IAA. This technology ensures the optimal temperature for fuel cells and offers up to 50 kW more cooling capacity in a given installation space. This enables a reduction of the required fan performance and reduces hydrogen consumption by up to 1.5 percent.

At the moment, hydrogen is the renewable fuel with the greatest potential to decarbonize the transportation sector. Several hydrogen engines are currently being tested at MAHLE. This year, DEUTZ, another engine manufacturer using MAHLE components, will enter series production. This flagship project will first focus upon stationary engines before expanding to mobile, off-highway applications. “We are very confident that serially-produced hydrogen engines will enter widespread use as early as this decade,” said Arnd Franz.

But even the most modern and sustainable truck is useless without the right infrastructure. “We welcome the fact that the EU has set targets for the expansion of charging and refueling facilities. Still, increased efforts in this sector will be needed to serve a broad fleet of zero-emission vehicles,” Franz said. “The member states are now called upon – and we hope that they will go beyond the minimum and accelerate expansion efforts. This will ensure that industry – and, especially, the transport industry – receive the planning security they need.”

Franz reiterated that, for users to invest in emission-free vehicles, it must make sense economically. Legislators, then, should create a framework which allows the market to build climate-neutral drives. In lieu of meticulous requirements requirements and technological regulations, renewable energy sources should be promoted with market-based instruments, said the CEO. This could be achieved by, for example, taking the effect upon the climate into consideration when levying taxes, tolls or other payments.

Arnd Franz cited synthetic fuels – or biofuels, until synthetic fuels are more widely available – as energy sources which should not be underestimated. These fuels could make an additional contribution to the reduction of carbon emissions in the transportation sector. Some regions, such as South America or India, are already focusing fully on biofuels. MAHLE also utilizes them wherever possible. For example, in Germany, the company uses the environmentally friendly HVO 100 fuel in its shuttle traffic between the central warehouse in Freiberg am Neckar and its two plants in Vaihingen an der Enz and Mühlacker, saving up to 90 percent carbon in the process. In addition, the Group has converted the approximately 70 diesel vehicles in its fleet in Stuttgart to HVO 100 – reducing annual carbon emissions by up to 250 tons.