In the heart of Melbourne’s southeastern suburbs, the suburb of Narre Warren used to experience significant traffic congestion at Webb Street, where it intersected with a rail level crossing. Over 13,000 vehicles passed through the intersection every day and the boom gates were down for up to 33 per cent of the morning peak travel time.

Recognizing the urgency to address this issue, the Victorian Government initiated the Webb Street Level Crossing Removal Project to eliminate this congestion and enhance the overall transportation system’s safety and efficiency by separating vehicles and trains.

To achieve this, one-kilometre section of the rail line needed to be elevated, with the crossing over Cranbourne Rd requiring two massive steel half-through bridges weighing 680 tonnes each. However, constructing the bridge using traditional stick-built methods would have required extensive road closures, causing major disruptions to Cranbourne Road, a key arterial in the suburb. The challenge was to work within a built-up urban area with limited space while keeping the arterial road operational for as long as possible.

Mammoet, renowned for its engineering and operational expertise, was tasked by McConnell Dowell, the project’s principal contractor, with devising a solution that mitigated the impact on the public.

Drawing on Mammoet’s extensive experience with bridge projects globally, the team proposed an Accelerated Bridge Construction (ABC) approach. This method involved fabricating the bridge offsite, in a convenient location near its installation point, then transporting it to its final position and installing it in a few days or hours. This minimised the project’s footprint and avoided extensive road closures.

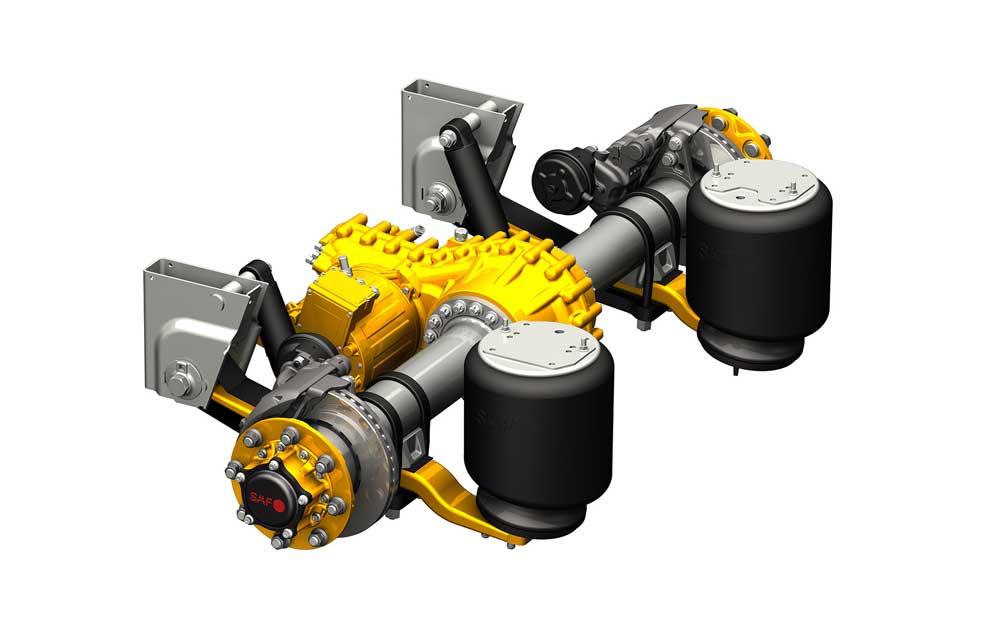

Utilising Self-Propelled Modular Transporters (SPMTs) in combination with the JS500 jacking system, Mammoet executed the operation with precision. First, the SPMTs raised the bridge sections from 1.5m to 4.2m high to prepare for the main jacking operation. Next, with SPMTs reconfigured and JS500 jacking units secured, the team jacked up the bridge to a transport height of 9m, ensuring clearance over street furniture and other obstacles.

Transporting the 50-metre-long, 680-tonne bridge sections through Narre Warren’s congested streets with houses, trees and power lines required thorough planning. The team carefully navigated the route, and once at the installation location, the bridge sections were gently jacked down onto their foundations. The selected installation methodology not only minimised traffic congestion, but also mitigated safety risks typical in traditional construction methods.

The new rail bridge rises over Narre Warren, with cars, pedestrians, and cyclists now traveling under the new bridge, and stands as a testament to the collaborative efforts of all involved. This project showcases how engineering excellence and innovative solutions can significantly improve urban infrastructure and community wellbeing. The level crossing was the 14th removed by the Victorian Government on the Pakenham Line, with more work underway to make the line boom gate-free by 2025.